As global manufacturing advances toward smart, precise, and sustainable practices, four core challenges have emerged: spatial integration, high-precision control, modular design, and energy efficiency.

HIWIN, a leader in motion control technology, introduces its latest automation solutions to meet these demands: the KH Series Single-Axis Robot, DCRK Series Cartesian Robot, and Miniature Ballscrews and Linear guideways. These innovations are widely adopted in automation, semiconductors, biomedical, inspection, and renewable energy industries, helping manufacturers achieve high efficiency, precision, and sustainability.

1. KH Series Single-Axis Robot: Optimal Modular Design for Space-Constrained Automation

The KH Series features high positioning accuracy (±0.005 mm), reliability, and versatile modular configurations. It supports high-speed linear motion up to 5 m/s and offers two structural types: KHM (lightweight) and KHT (torsion-resistant), addressing different rigidity and installation space requirements.

With dedicated selection software, users can quickly choose suitable models based on stroke, load, precision, and speed, and download 2D/3D CAD files to accelerate design and system integration.

Modular design enables rapid assembly of 2-axis, 3-axis, or gantry-type positioning platforms, ideal for space-limited and high-precision applications such as optical inspection, dispensing, laser cutting, and 3D printing.

2. DCRK Series Cartesian Robots: Modular Multi-Axis Platform for Precision Control

Built on HIWIN’s KK Series single-axis modules, the DCRK Series integrates standardized adapter plates and HRSim offline simulation software. It supports various configurations including cantilever, cross-type, and gantry-type platforms.

With repeatability up to ±0.005 mm and maximum speed of 1 m/s, it can be paired with HCR4 controllers and E1 servo drives for synchronized multi-axis control and efficient motion planning.

The DCRK Series enables rapid deployment and is suitable for semiconductor wafer handling, biomedical assembly, electronics dispensing, and inspection. It also replaces traditional hydraulic and pneumatic systems, reducing energy consumption and maintenance costs.

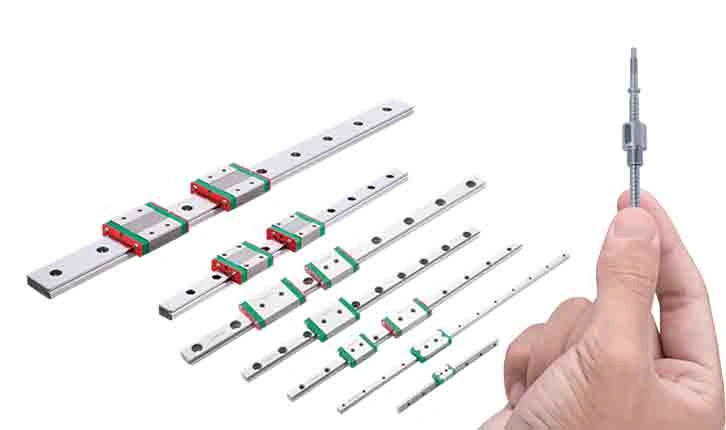

3. Miniature Ballscrews and Linear Guideways: High-Efficiency Transmission for Compact Precision Systems

In compact & high-precision equipment design, the size and performance of transmission and guidance components are critical. HIWIN’s Miniature Ballscrews and Linear guideways deliver high-precision and high-load motion control in a compact form factor, offering four key advantages:

• Compact size: Ideal for space-saving micro-mechanism designs

• Low friction and smooth motion: Enhances efficiency and reduces energy consumption

• Easy replacement and integration: Simplifies maintenance and design workflows

Diverse mounting options and materials: Supports customized applications

Application includes medical devices, optical platforms, wafer inspection, micro actuators, robotic finger joints, micro optical alignment stages, semiconductor inspection modules, and micro robots.

Engineering the Future: HIWIN’s Response to Four Key Manufacturing Trends

HIWIN’s latest product lineup—KH Series, DCRK Series, and Miniature Ballscrews and Linear guideways—addresses four major trends in advanced manufacturing:

• Spatial Integration: Micro-designs enhance layout flexibility

• Modular Design: Accelerates deployment and multi-axis integration

• Precision Control: High repeatability supports advanced processes

• Sustainable Efficiency: High-performance transmission reduces energy consumption and carbon emissions

These solutions not only improve process efficiency and product quality but also help enterprises build core competitiveness in global markets. HIWIN remains committed to innovation and customized services, leading the manufacturing industry toward a smarter, more efficient, and sustainable future.