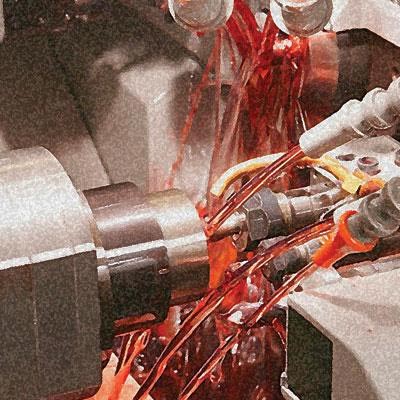

Hangsterfer’s cutting oils are recognized by Swiss-Style screw machine manufacturers around the world. Hard-Cut has improved tool life and surface qualities by as much as 300%. In addition to the lubricity provided at the cutting zone, our cutting oils provide excellent lubrication for the machine’s slides, guide bushings, bearings, and spindles. Some can even be used in bar feeders.

Hangsterfer’s Hard-Cut Next Generation® Series is formulated with the industry’s safest chlorinated extreme pressure additives, and our Missile Lube series is both chlorine and sulfur free.

No matter what the requirement, Hangsterfer’s has a cutting oil solution.

Hard-Cut®

- Hard-Cut 5118 A great oil for broaching, gear hobbing and automatic turning of larger bar stock diameters.

- Hard-Cut 5258 Generally used as a tapping fluid. It can also be used in heavy duty gear working, broaching and fine blanking.

- Hard-Cut 5258 Light A unique cutting oil intended for use in Swiss-Style automatics which are dedicated to very difficult to machine alloys, especially high temperature alloys.

- Hard-Cut 5318 Based on Hard-Cut 531, Hard-Cut 5318 is great for use in both CNC or Cam-style automatic screw machines. Usually used on larger diameter bar stocks.

- Hard-Cut 5418 An outstanding all-around cutting oil. It can be used in Swiss-Style automatics, milling machines or light stamping.

- Hard-Cut 5518 Ideal for turning small diameter bar stocks in CNC automatics.

- Hard-Cut 5618 Another unique product from Hangsterfer’s, Hard-Cut 5618 is used in grinding, horizontal machining, Swiss-Style turning, light stamping and forming.

- Hard-Cut NG and NG CF Hard-Cut NG is the Next Generation®, in the full line of straight oils developed, manufactured and offered by Hangsterfer’s.

- Hard-Cut NG 22 and NG 22 CF NG means this is the Next Generation® of Hard-Cut 22 and contains an infused combination of synthetic and vegetable compounds and derivatives. Delivers extreme pressure and anti-wear additives to the tool work-piece interface without compromise to other features that you expect.

Missile Lube®

- Missile Lube 1 This is the heavier of the three oils. The viscosity makes it suitable for use in many CNC lathe applications including Swiss-Style automatics.

- Missile Lube 1 XL This is the most popular of the three Missile Lubes. It can be used in virtually all metalworking applications that require a chlorine-free and sulfur-free cutting oil.

- Missile Lube 1 XXL This is an especially low viscosity version of Missile Lube 1XL.

CC Series

- CC 10 Hangsterfer’s CC oils are designed for light and medium duty metalcutting and metalforming operations.

- CC 22 These economically formulated oils are blended under the same quality control standards set for the premium Hard-Cut® Series.

- CC 46 Hangsterfer’s CC oils are designed for light and medium duty metalcutting and metalforming operations.

- CC 90 Hangsterfer’s CC oils are designed for light and medium duty metalcutting and metalforming operations.

- CC 222, CC 332 and CC 442 These are modern versions of the classical heavily sulfurized and chlorinated cutting oils. The old style dark sulfur and strong odors have been replaced with modern technologies that are light color and low odor.

Grinding Oil

- Grinding Oil 1 Grinding Oil 1 is designed for grinding with diamond and CBN wheels. It can be used for grinding high-speed steel, cobalt, carbide, ceramics and hardened steel. Grinding Oil 1 can also be used in grinders that require the same oil for both lubricating the machine and the wheel/workpiece interface.

- Grinding Oil 2 Grinding Oil 2 can be used for grinding high-speed steel, cobalt, carbide, ceramics and hardened steel. Grinding Oil 2 is intended for use in grinding machines that use the grinding oil for machine lubrication.

- Grinding Oil 32 Grinding Oil 32 is compounded with both synthetic and natural lubricity additives. Grinding Oil 32 is designed for grinding with diamond and CBN wheels.

PC Series

- Hangsterfer’s introduces a new series based on “Polar Cutting” technology and advanced “Very High Flash Point” (VHF) chemistry.

The combination of the Polar technology and VHF chemistry takes the metalworking process to new heights.

- PC 10 / PC 20 / PC 28 / PC 45Tapping/Misting

- SuperAllMist Provides extreme adhesion to the tool and workpiece.

- SuperAllTap, SuperAllTap CF, SuperAllTap Light SuperAllTap is recognized as the ultimate in high quality tapping compounds.

- Aqueous cleanable, oil free. SuperAllTap CF does not contain chlorinated paraffins or high concentrations of sulfur.