According to Trend Force’s research, green factories are driving the global smart manufacturing market, which is expected to reach $620 billion by 2026. HIWIN’s intelligent and innovative components continue to evolve, providing simple, safe, and modular designs that comply with ESG energy-saving and environmental protection trends. By enabling real-time remote monitoring of machine conditions to avoid unexpected downtime, optimizing machine maintenance cycles, and promoting energy-saving, HIWIN is becoming your best partner in achieving a green and smart factory.

Real-Time Monitoring and Efficiency Improvements

By using HIWIN’s intelligent components, customers can monitor the operating status of the components in production machines in real-time, preventing unexpected downtime. With normal machine operation and high-quality production, the overall equipment efficiency (OEE) of the factory can be improved, while AI helps achieve ESG results such as energy savings and carbon reduction.

Predictive Maintenance and Smart Lubrication

The Ballscrew and Guideway, being precision components installed inside the machine, are difficult to assess without disassembling the machine. However, with HIWIN’s dedicated sensors and advanced functional algorithms, users can monitor vibration data, temperature measurements, and intelligent lubrication analysis during operation. This enables life prognosis, allowing maintenance planning to be arranged in advance to prevent unexpected shutdowns or defective products.

Furthermore, the dedicated sensor and computation software assist customers in big data analysis, using AI to analyze lubrication conditions. In the past, lubrication was based on experience or a fixed schedule. Now, with frequency conversion lubrication, the system detects when oil needs to be added and automatically dispenses it, allowing precise adjustment of lubricant volume. A customer reported that after using the system for over a year, they saved 143 liters of lubricant and reduced carbon emissions by 140 kg annually.

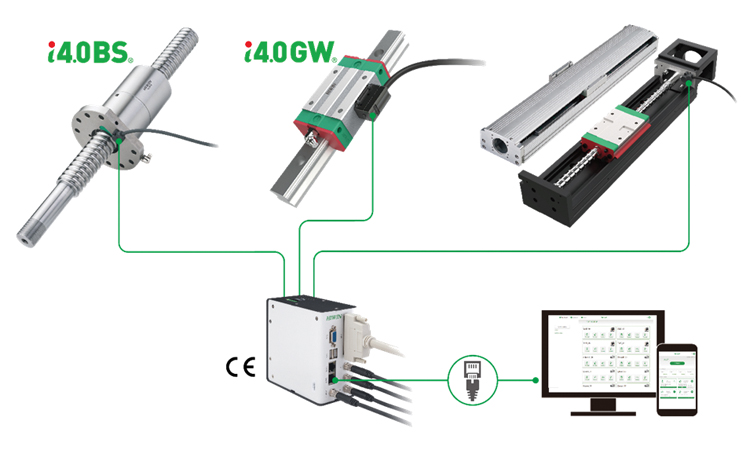

Intelligent Ballscrew i4.0BS®

HIWIN’s Intelligent Ball Screw i4.0BS® offers various intelligent functions through HIWIN’s self-developed vibration-temperature hybrid sensor and edge computing module with built-in expert algorithms. Key features include life prognosis, temperature and vibration monitoring and reminders, intelligent lubrication, intelligent warm-up, and DAQ data acquisition. This allows users to quickly implement digital transformation and upgrade machinery to smarter operations.

Intelligent Linear Guideway i4.0GW®

The Intelligent Linear Guideway i4.0GW® is ideal for dual-axis platforms commonly used in the semiconductor industry, particularly in AOI testing or wafer processing. It provides vibration and temperature monitoring, abnormal condition reminders, and DAQ data acquisition. These features enable semiconductor SI manufacturers to carry out secondary development and reuse, improving the overall efficiency of their operations.

Intelligent Single-axis Robot iSR

The Intelligent Single-axis Robot iSR is designed with a modular system to meet the needs of intelligent production across various fields. Fully compatible with i4.0BS®, the system offers a comprehensive intelligent solution. The combination of these features allows customers to easily upgrade to an intelligent system, helping enterprises achieve more efficient and smarter production operations.

Driving Smart Energy-Saving and Efficiency

Through these innovative smart components, HIWIN not only addresses customer pain points related to maintenance schedules and improves production efficiency but also helps achieve smart energy savings. These components are essential driving forces for customers to reach their goals of creating a smart factory.