The new VOLLMER VGrind infinity linear grinding machine is an all-rounder for the flexible machining of rotary tools made from different cutting materials.

One for all – this is the motto according to which sharpening specialist VOLLMER has developed and launched its new VGrind infinity linear tool grinding machine. The machine is the all-rounder for the flexible production of rotary tools: It can precisely, quickly and energy-efficiently machine precision tools with diameters from 0.2 mm to 200 mm made of different cutting materials such as carbide, high-speed steel, PcBN or ceramic. Automation and digital solutions from the VGrind infinity linear enable unmanned operation around the clock – from small batch sizes and special solutions to series production.

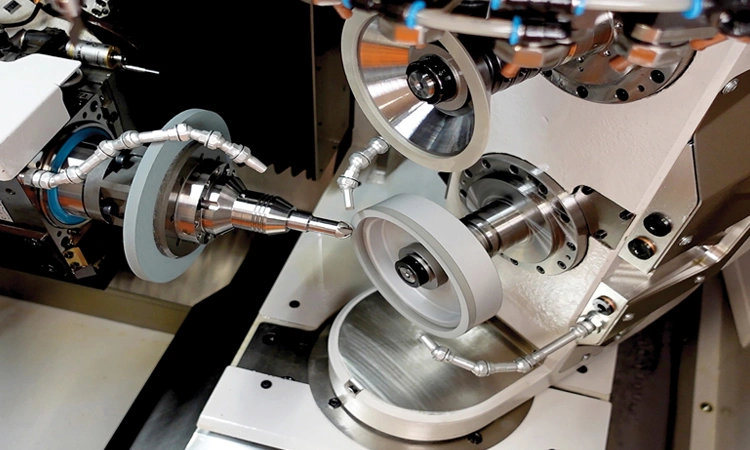

Nomen est omen with the VGrind infinity linear grinding machine from Biberach-based sharpening specialist VOLLMER: The machine offers infinite versatility for the high-precision production of numerous tool types with different sizes. The VGrind infinity linear automatically machines several cutting materials such as carbide, high-speed steel (HSS), PcBN (polycrystalline cubic boron nitride) or ceramic in a single set-up. The basis for the precise sharpening processes are two vertically configured grinding spindles, which enable efficient multi-level machining and thus eliminate problems related to fixed and floating bearings that are otherwise typical of machines. In addition, the grinding wheel set at the pivot point of the C axis and the wear-free linear motors on the X, Y and Z axes ensure repeatable and stable tool production at all times.

The all-rounder adapts to any sharpening process

Thanks to the configurable spindles, tool manufacturers can customise both the speed and the power for each tool and cutting material. The optimised spindle transmission ratio guarantees a constant torque, which is delivered by the compact, powerful and energy-efficient motor. The machine rigidity of the VGrind infinity linear and the intelligent cooling concept, which ensures thermal stability with plate heat exchangers, achieve the required precision at the cutting edge. If required, the

VGrind infinity linear also runs through a defined warm-up programme for thermal stability within a few minutes at the start of a sharpening process. As soon as all operating parameters are within the target range, scheduled production starts automatically.

In terms of tool dimensions, the VGrind infinity linear is capable of machining filigree micro tools with diameters from 0.2 mm up to large drills and milling cutters with diameters of 200 mm – and all this with tool lengths of up to 360 mm. The machine has various steady rest systems for both short and long tools, which ensure precise machining with the integrated laser measuring system. The all-rounder even masters fully cylindrical tools up to 32 mm in diameter.

Automation for round-the-clock production

Several automated systems enable unmanned operation around the clock. Tools with different shank diameters can be gripped and the HP 170 pallet magazine automatically feeds up to 900 shank-type tools into the machine. The HC 4 and HC 4 plus chain magazines can be used to provide different shank-type and HSK tools and the internal pallet loader offers space for up to 300 shank-type tools. An eight-position grinding wheel changer provides maximum autonomy and a wide range of variants for tool production. In addition, the IoT gateway integrated as standard controls the data flow between the machine and the digital environment.

“Customers can use the VGrind infinity linear to automatically produce small batch sizes with variable tool diameters or even large series, and the machine also has the flexibility to set up complex sharpening processes quickly, precisely and reliably,” says Tobias Trautmann, Managing Director of VOLLMER. “With this machine, we have an all-rounder that we bears the name ‘infinity’ for a reason, as it opens up endless possibilities for customised tool grinding.”

For more information,

www.vollmer-group.com![]()