In a fast-paced manufacturing landscape, staying ahead means being efficient and responsive. Manufacturers that rely on external suppliers for rolled cylinders, curved beams/profiles, or tank heads often contend with extended lead times and high shipping costs. These oversized parts also demand extensive storage space, driving up overhead.

By shifting forming and rolling operations in-house, companies can reduce delays, improve flexibility, and gain greater control over quality and timelines. Investing in modern forming technologies is a strategic move—improving turnaround, refining craftsmanship, and positioning your business as a reliable and agile partner.

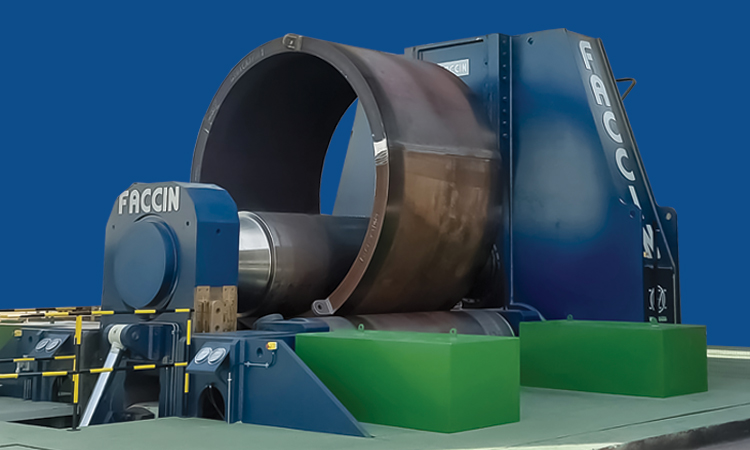

Performance Without Compromise: Why Choose Faccin Group

At Faccin Group, we recognize that cutting-edge forming solutions are vital to today’s manufacturing operations. As an international leader, our portfolio includes high-capacity machines offered through our trusted brands: Faccin, Roundo, and Boldrini.

Our product lineup features precision-engineered machinery designed for demanding applications:

Plate Rolling Machines: Options include 2-roll, 3-roll, and 4-roll models, capable of handling plates over 300 mm thick.

Profile, Pipe & Beam Benders: Robust 3- and 4-roll machines engineered for high-section modulus steel profiles (up to 20,000 cm³), with fully tailored configurations.

Head Forming Solutions:

- Automated dishing presses with integrated manipulators for blanks up to 12,000 mm in diameter.

- Hydroforming presses built to form plate up to 8 mm thick (standard).

- Flanging machines with capacities for cold form up to 80mm and hot spin up to 200 mm.

Special Equipment:

- Rolling lines designed for wind tower production, both onshore and offshore.

- Machines engineered for heavy foundations—monopiles, transition pieces, jackets,tripods and floating.

- Heavy-duty plate rollingmachines tailored for Oil & Gas applications, including full-spectrum component production.

- Plate rolling lines dedicated to the pharmaceutical and food industries with ZERO CONTAMINATION design.

- Robust rolling machines for vessel fabrication, aerospace, and marine industries.

- Plate levellers built specifically for high-strength, military-grade materials.

- Presses for hot and cold forming of nuclear-grade components.

- Straightening presses for naval and defense-related high-tensile structures.

Bespoke Engineering: We excel in tailoring machines to meet specific customer needs, all crafted through our end-to-end in-house production process.

Pushing the Boundaries of Forming Technology

Innovation fuels everything we do at Faccin Group. Our R&D team partners directly with manufacturers to co-create solutions that push technical boundaries—enhancing efficiency, operator safety, and process reliability.

Faccin Group Unveils Next-Generation Forming Technologies

- 4-Roll e-drive Plate Roll with Linear Guides Design (e-Drive).Save energy. Roll strong

The new Faccin 4-roll plate roll with e-drive is a best-case engineering choice. Electricity and hydraulics are perfectly combined to deliver optimal performance across a wide range of operating scenarios. The machine minimizes environmental impact: lower energy consumption by up to 35%, reduced oil usage up to 70%, and significantly less noise up to 15dB. At the same time, it maximizes results – greater efficiency, higher speeds, and increased capacity. It delivers rolling speeds of up to 10m/min, enhanced forming capacity, and exceptional process efficiency. In short: more output, fewer resources.

- HMI v.2 software: Designed to Impress. Built to Perform

Elegant visuals, smarter workflow, total precision. Experience the difference – test the new CNC software live at Fabtech Chicago.

- Ergonomic console with wireless control system. Freedom to Move, Power to Control

A revolutionary wireless console gives operators full mobility and control over rolling operations and machine accessories. Easy to use and highly flexible—ideal for streamlining automation.

Advanced Plate roll hydraulic system: Partnering with a top hydraulic supplier, we’ve developed a system that keeps machines running even during pump maintenance—minimizing downtime and maximizing productivity.

Eyebend – Laser-Based Radius Measurement System: Designed to quickly, and accurately, and automatically measure the developing plate radius during the rolling process. This revolutionary system provides real-time feedback and radius self-correction automatically through the CNC control.

Boldrini Hydra-X for Dishing Presses (Patent Pending): Hydraulic efficiency redefined—80% less oil, unparalleled ram control, reduced noise, and superior shape tolerance. Fast and intuitive axis controls elevate operator comfort.

- Boldrini Electric Manipulator (Patent Granted Certified): The world’s only patented manipulator with electric and Cartesian axes on the single-lifting-wheel side for handling discs up to 3,500 mm in diameter. Fully CE-compliant and uniquely engineered for unmatched safety and precision.

- Boldrini Hydra-XF for Flanging Machines (Patent Pending): The world’s first Active Flanging Control System. Guarantees forming accuracy for plates from 305 to 635 mm minimizing plate thinning thanks to the active pressure control.

Process Consultancy Service

At Faccin Group, we have established a dedicated team of engineers within our Technical Department to provide expert metal forming consultancy for both hot and cold processes. Leveraging state-of-the-art 3D finite element software, we are now able to simulate the 3D process in detail. This advanced capability allows us to simulate how the plate behaves during forming, delivering dynamic and highly accurate results.

For more information,

www.faccingroup.com