For over six decades, the Faccin Group has remained at the forefront of the metal forming industry, positioning itself as a global leader in the manufacturing of top-quality metal forming machines. The group’s unwavering commitment and dedication to excellence are evident through its three leading brands – FACCIN, BOLDRINI, and ROUNDO, which offer a vast array of plate rolls, angle rolls, dished end lines, and integrated solutions for rolling, bending, and forming metal sheets, profiles, and heads.

Faccin Group’s exceptional standing in the industry can be attributed to its remarkable product development department. The company boasts of a team of in-house technical designers and engineers who possess extensive expertise and a relentless drive for enhancing the group’s offerings, particularly in the realm of energy efficiency. Consequently, its machines surpass those of its closest competitor by an impressive 35 to 40% in terms of efficiency. Additionally, customers can now access a wide range of new accessories and upgrades.

Limitless Possibilities with Siemens-CNC PGS-Absolute

“Through our close collaboration with our esteemed customers, we are thrilled to introduce the latest CNC software upgrade. This new cutting-edge CNC seamlessly merges Roundo’s legacy with FACCIN’s technology, simplifying operations but also enhances the performance of operators. Now, with just one exceptional CNC solution, you can effortlessly handle both plate and angle rolls, setting new standards in efficiency and productivity,” reveals the company.

The latest version of the Siemens CNC machine has been significantly improved with a variety of state-of-the-art additions. These additions include enhanced feeding table alignment function, an advanced wind tower calculation capability, and speed indicators that are equipped with a joystick speed limiter function.

Moreover, the upgraded Siemens CNC -PGS-Absolute™ – now offers an unlimited number of controlled axes for automation, allowing for more efficient and seamless operation. Additionally, the PGS-Absolute™ has a new user-friendly interface that simplifies programming, making it easier for operators to navigate and utilize its functionalities.

Moreover, the upgraded Siemens CNC -PGS-Absolute™ – now offers an unlimited number of controlled axes for automation, allowing for more efficient and seamless operation. Additionally, the PGS-Absolute™ has a new user-friendly interface that simplifies programming, making it easier for operators to navigate and utilize its functionalities.

In Faccin’s suite of advanced features for optimizing performance and efficiency, the upgraded Siemens CNC – PGS-Absolute™ offers program fine tuning including dynamic program modification, correction factors for pre-bending and rolling, as well as automated correction based on measured results. The new software enables you to effortlessly create complex shapes and provides comprehensive production management tools, including graphic real-time simulation and automatic re-alignment for conical plates.

In order to maintain seamless operations and minimize downtime, it is imperative not to overlook the importance of smart maintenance solutions (alarms, a robust maintenance program, and advanced I/O monitoring) included in this upgrade.

Enhance Performance with Innovative Accessories/Services

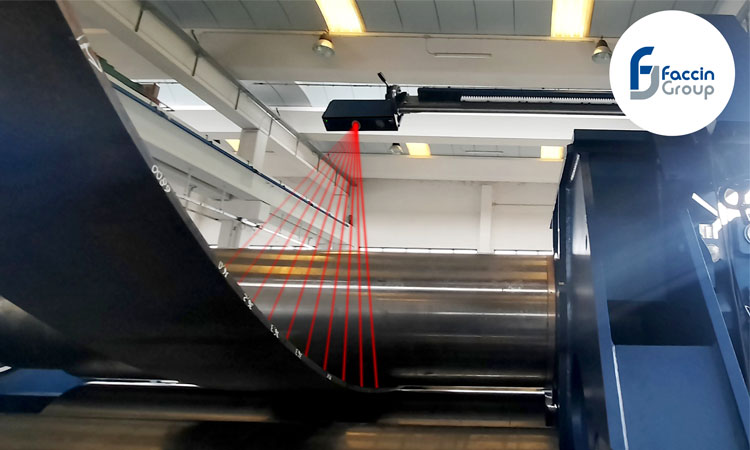

“To provide additional value to our esteemed customers we provide as an extra service a range of measurement and correction solutions such as the digital sweep interface for radius measurement accuracy, the repeatable hands-free precision with the innovative EyeBend™, real-time automatic bending correction, and a convenient multi-step rolling feature,” elucidates Faccin.”

“For immediate assistance, an innovative Cloud Based Remote Service Management System is also available. This cutting-edge system allows you to access remote tele-assistance, production monitoring capabilities, capacity management,preventive maintenance, cloud program backup services, and online documentation. With immediate assistance at hand, you can rely on our professional services to meet your needs,”