The history of computer numerical control (CNC) machines dates back seven decades. During the 1950s, CNC technology was difficult to introduce due to manufacturers’ skepticism. Today, it is hard to imagine the world of manufacturing without CNC machines. In material-removal processes, a CNC machine has become the central link that determines the functional capabilities of a manufacturer. CNC machining centers are complex machines that continue to evolve and improve. The advancement of CNC technology is based on the progress in various fields such as main spindle and its bearing units, machining slideways, high-velocity drives, computer engineering, hydraulics, electric motors, robotics, sensors, etc. When compared to a conventional machine with mechanical parts, the share of modern digital CNC machines is significantly higher.

CNC technology will continue to be the backbone of machining methods in the near and far future. The development of CNC machines is intended to increase versatility, productivity, stability, reliability, and accuracy of a given machine. These targets are ongoing milestones that assure contemporary machining results. The leap forward relates to machining centers that combine subtractive and additive technologies being CNC machining and 3D printing. At the same time, a complete rethink of CNC advancement has been brought about by INDUSTRY 4.0 and the concepts of smart manufacturing. In a smart metalworking factory, there is information exchange between the real world of CNC machines and a virtual world that functions according to features of the machined parts and their respective theoretical characteristics. Smart balancing on the boundaries of these worlds and analyzing the real-time information contributes to decisions and corrections that are made by computer-controlled units.

The element, which is much smaller, substantially cheaper, and considerably less complicated when compared to a CNC machine, is a cutting tool which is the link that directly removes material from a workpiece and closes the process of “machine-workpiece”. Due to objective reasons, this element is subjected to less fundamental changes and frequently identifies the cutting tool to be the weakest link in the processes, which also limits system capabilities. Therefore, appropriate upgrading of cutting tools should be considered as an integral part in the progress of CNC technology.

A conventional approach to making cutting tools relates to designing innovative cutting geometries, using advanced cutting materials, and applying leading production technologies intended to improve tool life, ensure greater material removal rate (MRR), provide higher accuracy, and increase reliability. Nevertheless, INDUSTRY 4.0 trends in the development of CNC technology place priority on the digital component of a cutting tool.

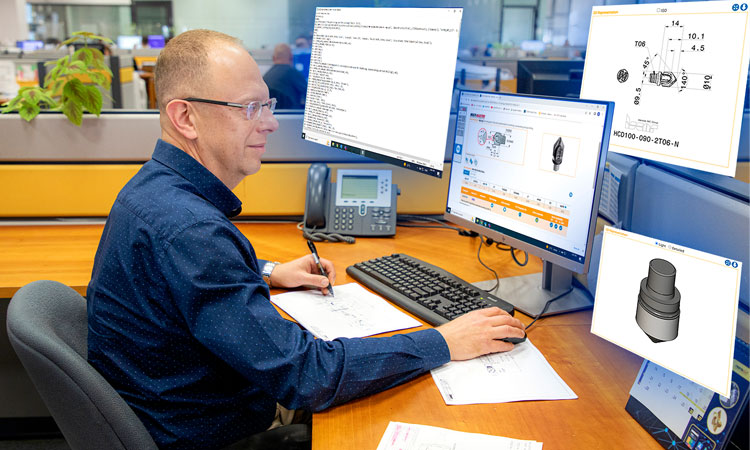

Information has constantly accompanied cutting tools even before INDUSTRY 4.0. Catalog data, tool drawings, and recommendations regarding applications were provided in printed formats and later as electronic formats and continue to be essential for metalworking. Computerization has affected customer support by providing expanded capabilities in the form of data. Various software applications have enabled selecting optimal tools and estimating tool life under specific machining conditions. The combination of ISCAR’s NEO-ITA and Power Consumption applications enable quick calculation of cutting forces, bending load, power consumption, finding suitable cutting material grade, the right tool for a specific application, and analyzing competitors’ products alongside other useful functions. Customers can easily access data and related information by use of computers and mobile devices. Notwithstanding, advancements in network communications have introduced the world of metal cutting to the virtual electronic world.

Digital twin technologies complement manufacturing processes. Machining modelling, collision checking, process optimizing to find best cutting strategies are only some examples. In a smart factory, the digital twin is the most significant brick of the foundation. Understandably, only a tool having its digital twin is acceptable for the smart factory’s toolroom.

The progress of CNC technology leads to new demands for cutting tools. A tool producer is expected to be a provider of a product that ideally combines a tool as a material object, its real-time digital twin, and an appropriate software environment. This allows the seamless incorporation of the tool data in CAD/CAM and virtual manufacturing, direct transmitting by Internet of Things (IoT) networks – tool packages and virtual assemblies.

To make tool representation clear for various computer systems, the ISO 13399 standard was developed and assures the platform’s independence. This standardization is necessary for other digital components of the tool package to unify data related to tool life, calculated loads, machining conditions, etc.

ISCAR’s digital tool component, which is based on the ISO 13399 standard, includes the following characteristics.

- E-catalogue with various search functions, updated promotion information and reference data.

- The .p21 file (a STEP file) includes a product identification class for a comprehensive tool data representation and exchange.

- 3D tool representation for computer modelling and CNC programming in accordance with the ISO 10303 standard (STEP).

- A 2D tool representation in DXF format for a planned process documentation, drawings, tool layouts and setup sheets.

- Virtual tool assembly options for turning, milling and holemaking tools intended for generated digital assembly twins in both 3D and 2D representations.

- NEOITA – ISCAR Tool Adviser, an expert system that recommends optimal tooling solutions for a specific application.

- The machining calculator and the cutting material grade optimizer software applications.

A rapid pace of industrial digitizing takes CNC technologies to new heights. This gives a boost to appropriate changes in the product range of a tool manufacturer and demands strong links between a cutting tool and its virtual digital component.

For more information, Website: www.iscar.in